Our shop is equipped with the latest in tube bending, tube manufacturing, swaging, cutting and bending equipment to accommodate your every exhaust need.

Check out our info video with Miller Welding.

While we specialize in and stock various items in mild steel, 304 and 321 stainless steel, and Inconel 625, please contact us to obtain information on custom quotes for all of your exhaust needs.

Mandrel Bending

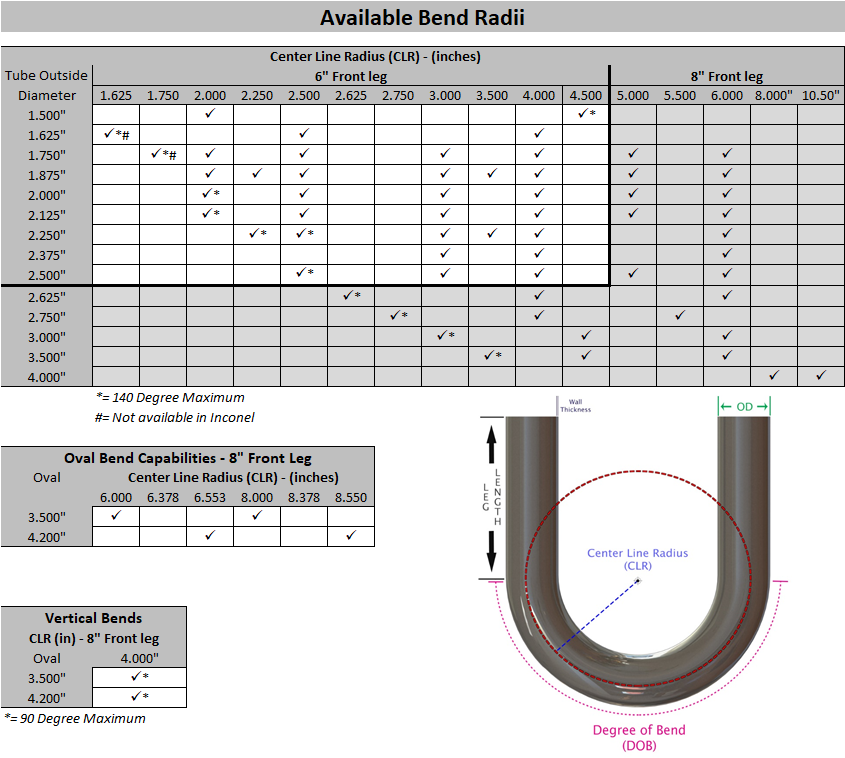

The charts shown here (which can be clicked to enlarge) are a comprehensive listing of the dies that ProFabrication has onsite for round and oval tube bending. An X indicates our current bending capabilities.

NOTE: If you need a specific center line radius (CLR) or diameter that is not represented in the chart below, please contact us. ProFabrication is always ready to add to our bend die inventory.

If you require a hard to find diameter or material type, please note that ProFabrication does tube manufacturing as well. Please see the Tube Manufacturing section of this page for further information.

The ProFab Oval Bend Advantage - We use oval material that has been run through a tube mill. We then mandrel bend the material using dies specifically designed to bend oval material. This gives us a more consistent bend and a bend that is easier to cut and fabricate.

Tube Manufacturing

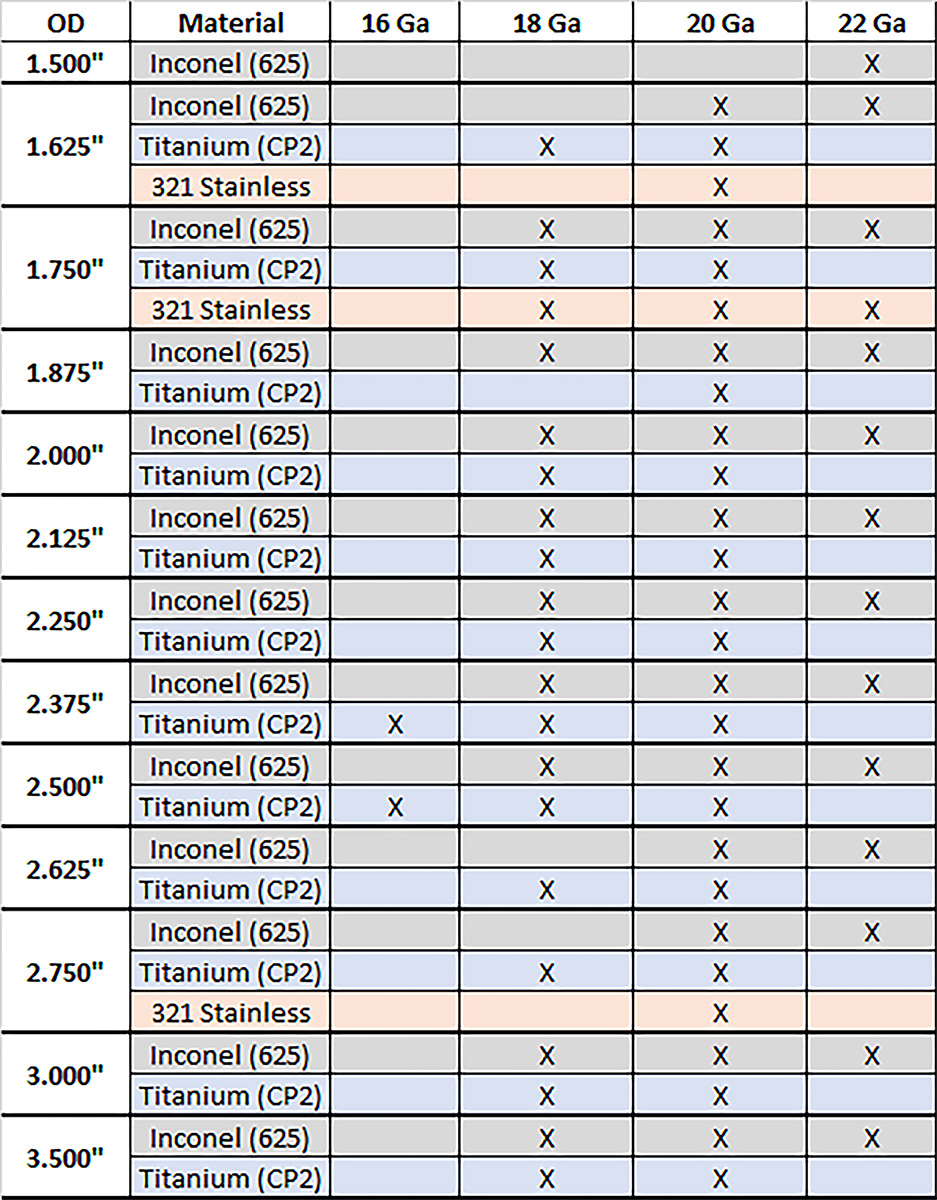

ProFabrication manufactures its own tubing from flat stock. This allows us to offer an extensive range of material types and gauges in a timely manner to our customers.

We specialize in exotic metals and hard to find material types, such as Inconel 625 and 321 Stainless Steel.

To manufacture tubing, a blank is sheared from sheet stock. The blank is then rolled and welded, using advanced equipment and a Tig welding process. The final product is then checked for accuracy. The product can then be shipped or bent on one of our mandrel benders.

We roll and weld material from 0.015” to 0.049” thick and 1 3/4" to 3 1/2" diameter with a maximum length of 28”.

See charts shown (which can be clicked to enlarge) here for in-house diameter and gauge capabilities.

Don't see what you're looking for?

Please email us or give us a call at the shop 704.795.7563.

Header Building

All ProFab headers are built to customer’s exact specifications, whether they consist of 1 piece or 100! We work together with the engine builder to improve dyno results and ensure compatibility with the chassis and specific car design.

After all boundaries have been established, our welding and fabrication department builds the initial set of headers using CAD models or a chassis supplied by the customer. To ensure repeatability of performance and clearance, a Jig is built for your specific header needs. We build the Jig directly from a customer-supplied header or from the initial build if you are bringing your car into our shop.

We fabricate and Tig weld your headers using precision-machined flanges with a wide range of tubing gauges available to guarantee your needs are precisely met. Mandrel-bent primaries and merge collectors increase exhaust velocity and performance.

What this means for you is the total assurance that your header will mount up seamlessly for best fit and optimal performance, whether your header is for your race team or your own personal hot rod.

ProFab headers are always finished and assembled, ready to bolt on to your (race)car.

At ProFabrication we take pride in our ability to produce superior quality products out of top-quality raw materials.

Header Repair

Racing headers are much more susceptible to damage than most people think. It is often a lot more difficult to detect than a simple crack or broken weld. That's the bad news. The good news is that stainless and mild steel headers can often be repaired to like-new condition for a significant cost savings over replacing them out-right.

Headers get extremely hot during a race; the heat makes the tubing of the headers a lot easier to bend. A car involved in a wreck can get a knock down at the merge collector that bends the tubing up near the exhaust flange.

Header tubes are selected for performance. To evacuate exhaust gases from the combustion chamber as cleanly and efficiently as possible, use a round tube with as few bends as possible. If the tubing becomes anything other than perfectly round, the interior surface area of the pipe is reduced, as is its ability to flow exhaust gases from the engine. This leads to backpressure.

While small dings and even small flat spots aren’t a big deal, kinked or bent pipe IS a big deal and should be repaired.

We repair headers in-house by replacing damaged tubes. It is far less costly than replacing the whole header. Merge collectors can be costly too, so even if that's all you manage to salvage, you’re still coming out ahead.

Header Repair Image

Tailpipes and Components

We have .130 wall tubing as an option for tailpipe material. ProFabrication offers four options of material thickness for COT tailpipes: .049 410 Stainless, .065, .083, and .130 wall AKDQ. We also have eight options for tailpipe (Boom-tube) heights available- 1 ¼ -1 ½ -1 ¾- 2- 2 ¼- 2 ½- 2 ¾- 3". We are offering tailpipe construction to any degree of process: custom-bent tubing and components, tack welded assemblies, or completely welded assemblies.

Teams count on ProFabrication to provide complete custom exhaust systems with the exceptional craftsmanship we've come to be known for. This coupled with our superior customer service makes our header systems, and hence, your team, tough to beat.

Merge Collectors

ProFabrication's merge collectors are engineered to achieve the high flow and velocity necessary to increase and broaden an engine’s torque curve and peak power. Each merge collector is Tig welded and incorporates a transition spike that is internally blended, making the transition from primary tube to collector as smooth as possible, thereby maintaining exhaust velocity and improving volumetric efficiency.

Other Types of Collectors

We also offer weld-on and formed collectors for most racing applications.

We manufacture an extensive selection of merge collectors for any application.

• 2 Way, 3 Way, 4 Way, and 5 Way Merge Collectors

• Y Merge Collectors

• Offset Merge Collectors

Our merge collectors are manufactured using fixtures from our tool & die department. This in-house advantage allows us better consistency in our merge collector product line.

We stock:

• 12 degree merge angles

• 15 degree merge angles

• 20 degree merge angles

in 4-into-1 and Y-merge collectors. Additional parts required to finish a merge collector include collector transition and straight pieces. They are available separately.

Our merge collectors are available in:

• 304 Stainless Steel

• 321 Stainless Steel

• 625 Inconel

• Mild Steel

Services

ProFabrication can complete any merge collector with a transition built to your specifications. If you do not see what you are looking for, please call us at 704.795.7563 to speak with a specialist about how we can best meet your merge collector needs. ProFabrication welcomes the opportunity to provide you with all your racing exhaust system needs!

Merge Collector Image

Mufflers

ProFabrication has been producing quality racing exhaust and components for over 20 years. We now offer Ultra Lightweight racing mufflers.

Our mufflers are made of thin gauge 304 stainless steel with TIG-welded construction. Each muffler is easily disassembled for renewal of cartridge materials. We offer several options for packing material (some lightweight, others more durable with slightly higher weight) and repack kits.

ProFab mufflers produce the highest performance at the lightest weight with outstanding durability. Dyno tests prove the use of freshly packed mufflers show no detriment to horsepower when compared to un-muffled systems.

Our mufflers are NOT street mufflers adapted for racing use, they are hand-built by our expert racing fabricators.

Modular Design

ProFabrication mufflers are designed with a removable and replaceable core for easier, faster repacks & rebuilds. The one-piece main housing allows extensions or turnouts to be welded directly to the outlet pipe without sacrificing rebuild-ability. The housing also allows for positioning the muffler anywhere in a system. With a “floating core”, our mufflers allow for clamp to and rigid mounting of the outlet pipe without risk of core damage.

IndyCars

In 2017, ProFabrication became an approved supplier of the Indy Car series. We build exhaust components for the race teams.

Oval Products

We stock horizontal oval bends, vertical oval bends, oval straight tube, and oval extensions.

In bends we have combinations of radii, oval tube diameter, and gauge to suit professional header builders, fab shops and racers alike. We are continuously adding to our oval tube capabilities and inventory.

Don’t see the oval bend or oval product you’re looking for? We offer custom oval bends and oval products in many configurations. Please call us at 704.795.7563 to speak with a specialist about how we can best meet your oval product needs.

Flanges

ProFabrication stocks CNC Header Flanges for a variety of head types, including: Ford, Chevrolet, Dodge, and imports such as Honda, Toyota, BMW, Mitsubishi, Porsche, VW and Ferrari.

ProFab stocks 3-Bolt Flanges in a variety of diameters. We also have 3D flanges available.

All CNC Header Flanges are machined on precision equipment. All header flanges are made from 3/8" or 1/2" thick 1018 cold roll steel or 304 Stainless Steel. They are made of 304L material and some require heat treating. The lower carbon content of these flanges allows for easier weldability.

Buy the best in CNC Header Flanges at ProFabrication. We welcome the opportunity to provide you with all your racing exhaust system needs. Check out the ProFab difference!

Hardware and Accessories

ProFabrication provides a sizable inventory of exhaust system related hardware and components for your exhaust system project, including:

• V-Bands/ Marmon clamps with machined sealing flanges

• Header Tabs

• Header Tab Bolts

• Exhaust Flanges

• Weld Bungs - including O2 Bungs and EGT Bungs

• Welding Rod

• Tools

We stock a selection of V-Bands and V-Band kits in stainless and Mild Steel to affix your bends, straight material, and collectors in your project.

Kits include a V-Band clamp and (2) Sealing Flanges.

ProFabrication has created a kit for Pro Mod cars to allow you to fine tune for downforce, speed, or the best combination of the two. This customizable, adjustable thruster kit takes the guess work out of maximizing your machine's power at the collector's end.